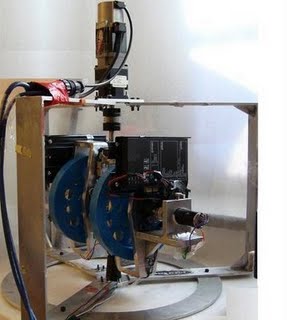

Consider the flywheels of the RelMachine. They are mounted in frames, on ball bearings to facilitate their smooth rotation. The frames themselves are affixed to the (rotatable) central machine axis. When we rotate the flywheel assembly about the central axis of the machine, what are the conditions that obtain? The flywheels have mass. They are being spun about the central machine axis. Under such conditions, the flywheels are being acted upon by the machine axis - the machine axis is exerting a centripetal force.

Wikipedia

http://en.wikipedia.org/wiki/Centrifugal_force

A mass undergoing curved motion, such as circular motion, constantly accelerates toward the axis of rotation. This centripetal acceleration is provided by a centripetal force, which is exerted on the mass by some other object. In accordance with Newton's Third Law of Motion, the mass exerts an equal and opposite force on the object. This is the "real" or "reactive" centrifugal force: it is directed away from the center of rotation, and is exerted by the rotating mass on the object that originates the centripetal acceleration.[5][6][7]

The concept of the reactive centrifugal force is used often in mechanical engineering sources that deal with internal stresses in rotating solid bodies.[8] Newton's reactive centrifugal force still appears in some sources, and often is referred to as the centrifugal force rather than as the reactive centrifugal force.

Now, so far the flywheels haven't themselves been spun up. Therefore, in accordance with Newton's laws, the flywheel then exerts an equal and opposite centrifugal force upon the central machine axis.

What happens if we first set the flywheels spinning to a large, fixed rotational speed ω z rpm and only then started spinning the entire flywheel assembly about the central machine axis? The answer to that question depends on whether or not there is a significant rate of change of angular acceleration in the motion of the flywheel assembly about the main machine axis.

CASE A

If there IS a significant rate of change of angular acceleration, the answer proceeds as follows:

In order to extrapolate the expected behavior of the flywheel in this case, we reason that since the flywheel is inductively suspended, we must look to the behavior of an inductor. An inductor RESISTS a rate of change of current through it.

Thus when an inductor begins to feel the surge of rate of change of current, it will correspondingly generate enough potential difference to overcome and cancel that current so as to maintain its previous state. However, if there is even so much as a tiny bit of capacitance coupled to the inductor, them the together form an LC circuit and will therefore have a unique threshold frequency peculiar to them. - This is an element of a low pass circuit, which means that any and all frequencies below the threshold frequency will receive a 'pass' from this circuit.

The exerted surge can have a periodic character or can be more of a simple speeding up character. Lets analyze the two.

If the surge is cyclical for example like this, the analysis is perfectly analogous to the LC low pass filter circuit. Thus all such inputs will meet the 'pass' condition of the low pass filter circuit.

Under such conditions, the circuit will resonate with the energy and some of it will leak into the ambient surroundings. The equivalent of this in the mechanical case would be the SHEDDING OF CENTRIFUGAL FORCE.

If the surge is more just a transient thing on the way to acheiving a steady torque used to accelerate the assembly to a large angular velocity about the central axis, this is what the time vs angular velocity, acceleration and rate of change of acceleration will look like.

We can see that the inductive phenomenon will only be effective for the following time periods: the beginning when the wheels starts speeding up about the central machine axis, and at the end, when the flywheels were brought to a stop. Thus the effect would be transient and barely noticed excepted at the beginning and the end of the operation.

CASE B

If there isn't a significant rate of change of angular acceleration: This is similar to situations where the flywheel is spinning and the assembly itself is

i) being moved in approximately straight lines,

ii) or being moved at constant accelerations

iii) or being moved at constant velocities.

Under such circumstances, relativistic effects are hidden from our view. The phenomenon proceeds as a Newtonian interaction.

ANALYZING THE KIDD EFFECT VIDEO

We can see from the graph at the very beginning of the Kidd Effect video, that there is large rate of change of acceleration being deliberately induced by vertical motor at the top of the Relmachine, in a cyclical fashion. Thus the flywheels respond as in CASE A.

Now, some energy from this capacitance-inductance circuit will 'leak' into the surroundings i.e. the flywheels will shed centrifugal force. It means the flywheels will lose part or all of their ability to produce a centrifugal force in response to the exerted centripetal force. This shedding of centrifugal force has consequences. The most direct consequence is that if there is a way the flywheels can move, either inwards or upwards they will move. The conditions governing the movement are as follows:

1. The flywheels are spinning fast enough (condition 1) and the applied rate of change of torque is large enough (condition 2) to over the gravitational force acting downwards, and the force rquired to forcibly move the flwheel vertically is less than the force required to move the flywheel horizontally (condition 3): Flight will result.

2. If condition 3 is not met, then if the conditions 1 and 2 are met, then we see what happens in the end of the video, when the flywheels forced themselves inwards.

3. If condition 3 is met but 1 or 2 are not met, then the RelMachine will show no net movement, but will show a net leakage of energy because the energy channel is open. Just not full. As conditions 1 and 2 are fulflled, the channel will fill up and the relMachine will fly. Until then, the leakage of energy to the gravitational field will steadily increase as we increase our ability to meet conditions 1 and 2 (ie we increase the flywheel speed or the rate of change of acceleration).

ANALYZING SANDY'S FIRST MACHINE

In Sandy's patent, he exerted forces on the flywheels in a slightly different, but nonetheless very creative manner.

"means for periodically forcing said masses towards one another from a predetermined position and allowing said masses to return to said predetermined position so as to generate a pulsatile force in said mounting means."

US Patent # 5,024,112

Thus the wheels were physically pushed towards the central machine axis. This is equivalent to the RelMachine's operation. In the RelMachine, that 'pushing' force is being exerted by the centripetal force, which in Sandy's machine, it was being done by a cam, in a very physical way.

Thus, in the case of his machine too, a cyclical consistent amount of lift will be delivered. Depending on the match between the resonance frequency of his machine and the applied cyclical torque, the output could have been suboptimal.

NEXT STEPS

I have determined that at this point, I must amplify the output. I will endeavor to do so in the coming weeks. I expect to run new, amplified experiments within the next 3 weeks.